On This Page:

The Latest ....

Used Tires Killed Reef -

Editorial Note: On Toxcity of Rubber Crumb

Rubber infill from used tires [pictures and text]

Tire Dust -- an article from November 2005 issue of Ecologist

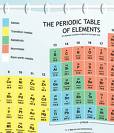

Four types of rubber infill [Melos]

"Hazardous Chemicals in Synthetic Turf," by William Crain and Junfeng Zhang

Banned in Sweden!

"Synthetic turf from a chemical perspective, a status report," by the Swedish Chemicals Inspectorate (March 2006): Background, Summary, Conclusions, Recommendations.

"Potential health and environmental effects linked to artificial turf systems - final report," by Norwegian Building Research Institute (September 2004).

"Myth of Rubberized Landscapes" by by Linda Chalker-Scott, Ph.D.

"Environmental impact of highway construction and repair materials on surface and ground waters. Case study: crumb rubber asphalt concrete," by M.F. Azizian, P.O. Nelson, P. Thayumanavan and K.J. Williamson

A Colorado Study

From the Horse's Mouth: Ten cate Thiolon Product Advisory

Response to citizen concerns: Wayland and Newton, Massachusetts

|

Concern over synthetic turf is not going away!

[Editor's Note] The Westport Brief on this site (see Introduction page) chronicled the epic struggle of a number of Westport moms and public health experts to get answers about the health and safety issues associated with artificial turf fields. The story of Patricia Taylor and her son, Liam, was recently the human-interest hook for a health news story published on October 28, 2007, in The New York Times:

"Liam would come home with the tiny [rubber crumb] particles in his cleats, in his clothes and in his hair... 'Kids are tracking it back home, into washers and dryers, on the rugs and in their tubs. It's not just staying on the field. It's migrating.'... [Because of health and environmental implications of rubber crumb] Liam Taylor and his mother are proceeding with caution. This year, he is on the soccer team at the Hopkins School in New Haven, which does not have a synthetic turf field, and his mother refuses to let him play at any school that does have one. 'My job is to protect my son,' she said. 'Now that there is evidence of out-gassing, he will not be exposed until the fields are proven safe.'"

Read more of this story by Jeff Holz, "Parents Raising Concerns Over Synthetic Turf," The New York Times, October 28, 2007, available at http://www.nytimes.com/2007/10/28/nyregion/nyregionspecial2/28turfwe.html?_r=1&oref=slogin. The story features also statements by physicians and public health experts, and calls for more study, caution and moratorium.

|

Toxic Turf [News report -- text and video]

News 12, Port Washington, Long Island, NY

October 15, 2007

Video clip: http://news12.cv.net/video/BLTURFST.wmv

Text: http://www.news12.com/LI/topstories/article?id=201493#%22

PORT WASHINGTON - The use of artificial turf fields at Long Island schools is growing, yet the jury is still out on whether they put children at risk.

Synthetic turf fields, like the 150 Landtech has sold to schools on the Island, are made with rubber from recycled tires. Grassroots Environmental Education's Doug Wood and other experts claim the used tires contain toxic metals and carcinogenic chemicals, and therefore so do the fields.

"Tires are so full of toxic chemicals they have to be disposed of in a special landfill," Wood said. "So why would you grind them up and put them on a field where kids are going to play?"

Ken Marlborough, athletic director for Port Washington schools, said Landtech assured him the artificial turf it installed was safe. Marlborough said the appeal of the $750,000 surface is its convenience.

"The real benefit I think is that [it] is truly an all-weather surface," he said. "Even in a heavy downpour with[in] a matter of minutes, the field drains and can be ready to play on almost immediately."

Landtech, which declined to speak on camera, said through a spokesperson that studies show the tire crumbs are not harmful.

News 12 Long Island decided to test the claims, taking a sample from the Port Washington field for lab studies. The content levels of heavy metals were within government limits. However, some cancer-causing chemicals were well in excess of state safety levels. Chrysene, for one, was present in amounts more than 1,250 times the safe limits.

Dr. David Carpenter, of Environmental Health and Toxicology, said the state Department of Health should impose a moratorium on the installation of artificial turf fields until enough research proves they are safe.

A prominent New York toxicologist is conducting a study and promises to release her results in the near future.

Doctor urges caution on fake turf

Lisa Chamoff, The Advocate [Stamford, Connecticut]

October 16, 2007

http://www.stamfordadvocate.com/news/local/scn-sa-nor.turf7oct16,0,2479037.story?coll=stam-news-local-headlines

WESTPORT - A expert on the environment and children's health told a small crowd at the Westport Public Library last night that parents should be wary of synthetic turf athletic fields, and he agreed that cities and towns should not rush to install the fields, which are made in part from recycled tires, until the health risks are determined.

Dr. Philip Landrigan, who heads the department of community and preventative medicine at the Mount Sinai School of Medicine in New York City, spoke about exposure to chemicals such as pesticides, lead and mercury, and how they affect children's' health.

Aside from the arguments that synthetic turf athletic fields are less costly to maintain than grass, Landrigan said the fields get very hot and can cause rough abrasions that are more likely to become infected.

After recently reviewing a report from New Haven-based Environment and Human Health Inc., Landrigan said he agrees that the shredded tires and the affect on children's health should be studied further.

The report centered on a recent study by the Connecticut Agricultural Experiment Station in New Haven.

The study found that under laboratory conditions the tire fragments released at least four dangerous compounds, including one recognized carcinogen, under slightly elevated temperatures. The compounds can irritate eyes, skin and mucous membranes. The rubber also was found to leach heavy metals into water.

The organization has asked for a moratorium on the further installation of the synthetic turf fields until more research is done.

"What we don't know at this point is to what extent do these toxic chemicals . . . get into kids' bodies," Landrigan said.

He noted a study being conducted by Rutgers University utilizing a robot that will move around the fields and take air samples about a foot above the surface to measure the amount of chemical exposure. He said it also would be a good idea to work with groups of parents and obtain urine samples of children who use the fields, to see if chemicals are passing through their bodies.

Landrigan also focused on the increasing incidence of asthma, childhood cancers and developmental disorders, such as autism. He said there are chemicals that haven't been tested for their possible toxicity, and children are more susceptible to exposure because they drink more water and often transfer substances to their mouths. Children also are still developing and they take longer to rid their bodies of chemicals, he said.

"We are conducting in our society a vast toxicological experiment," Landrigan said.

There is evidence for environmental causes of developmental disorders, including lead, methyl mercury and polychlorinated biphenyls, or PCBs, Landrigan said. He advised people to eat organic foods as much as possible, be informed about neighbors' pesticide use and encourage the use of "green" materials in schools.

A multiyear study to examine the influence of environmental factors in children's' health and development is under way, Landrigan said. The National Children's Study, led by the U.S. Department of Health and Human Services and the Environmental Protection Agency, will follow 100,000 children from before birth to at least 18 years of age.

"We believe it's our generation's best hope of detecting preventable diseases," Landrigan said.

Nancy Alderman, president of Environment and Human Health, said last night that she was pleased Landrigan addressed the synthetic turf issue.

One mother who attended the talk said she hadn't known about the concerns about synthetic turf, and that they surprised her. A field was recently installed behind Saugatuck Elementary School.

"I had no idea that the turf was so dangerous and a concern," said Joan McCullough, who has a 4-year-old daughter. "It's made me more aware of what my daughter can be exposed to."

|

|

Editor’s Note: In the news article about the health risks of artificial turf fields in Italy (below), reference is made to a substance called toluene. The article also refers to the European Union’s ban on PAHs in tire manufacturing beginning in 2007. In connection with these issues relating to rubber crumb, the readers may find of interest the following documents:

On tyre manufacture (UNEP/Basel Convention) [http://www.basel.int/meetings/oewg/oewg6/docs/oewg6_inf06.pdf] ,

On the EU’s registration, evaluation, authorization and restriction of chemicals program (REACH) [http://register.consilium.europa.eu/pdf/en/06/st15/st15315.en06.pdf] and regulation thereof [http://reach.jrc.it/docs/Reach_legal_text_en.pdf] and corrigenda [http://www.lifesciences.at/download.asp?id=1556]

On UK’s implementation legislation of the REACH [http://www.opsi.gov.uk/si/em2006/uksiem_20063311_en.pdf].

On call/report by Sweden’s KemI to ban the use of HA oils in tyre manufacture [http://kemi.se/upload/Trycksaker/Pdf/Rapporter/Rapport5_03.pdf] and press release [http://www.kemi.se/upload/Medier/Pressmeddelanden/2003/HA_press_release030327.pdf]

On restrictions on the use of toluene (EU) [http://eur-lex.europa.eu/LexUriServ/site/en/oj/2006/l_033/l_03320060204en00280081.pdf]

Italy: Synthetic turf fields will be cleaned up!

Corrado Zunino, Erba sintetica, allarme confermato “Quei campi vanno bonificati,” in La Repubblica, May 3, 2006 – reproduced in its entirety below and also available at http://www.repubblica.it/2006/04/sezioni/cronaca/campi-sintetitici-cancerogeni/conferma-rischi-cancro/conferma-rischi-cancro.html

[Translated in part for synturf.org by Elio Branca]

The former Italian minister of Health, Francesco Storace’s last act in office was to make public on May 2, 2006, the study of a commission that he had set up in order to examine the potential risks associated with use of rubber in artificial turf fields. According to the study, the synthetic turf fields in Italy are potentially cancer-causing. The study found levels of polycyclic aromatic hydrocarbons (PAHs), toluene (volatile toxic compound), and heavy metals to be higher than the legal limits. The PAHs pose risks to kidneys, liver, and lungs. According to the investigators at the High Institute of Health (Instituto superiore di Sanita), the inhalation of the dust from these substances pose a risk to soccer players. The commission, which also included physicians and lawyers from the ministry of the Environment, urged the adoption of a law to clean up the dangerous fields.

According to Professor Roberto Verna, the president of the commission, “It is clear that PAHs and toluene are a danger to health.” “We do not want to spread fear, but it is necessary to find a way to clean up the playing fields,” he said. “Let us say, all of the fields in Italy need to be examined, the 350 official ones and the dozens that have been installed without governmental approval,” he said.

Accroding to Verna, the inspiration for defining the danger of artificial turf fields comes from the law about greens paces and parklands. The study document will be sent to FIFA, the world governing body for soccer, and to the European Union: the European Union already has prohibited the production of rubber with PAHs after 2007. “This study is the first such work in Europe that has been undertaken by an independent commission,” said Varna. "The rubber in the fields,” he said, “must be treated like diary products: we must know about the origin of the rubber, the process and how its is made into its final form – to get a seal of approval/label of quality.”

According to Carlo Tavecchio, president of national league of amateurs (Lega nazionale dilettanti), “we have to open up 200 fields and take out/vacuum the noxious substances. The cost will be divided among the Federal soccer organization, the producers of the turf and management of the clubs.” This will be a titanic undertaking. Each full-size soccer field (11 v. 11) contains 130 tons of infill and costs between 300,000 to 650,000 Euros.

On the heel of the discovery of toxicity of the artificial turf fields, a pitched industrial battle is brewing between the producers of virgin rubber and recycled rubber, the big versus small. There is Olimpico that makes a product that is a mix of artificial grass and natural grass and does not need rubber. Then there are firms that manufacture foundations/underlay for artificial turf fields out of cork.

The commission noticed a great number of children’s playgrounds are on rubber surfaces that are produced by the sane firms that manufacture the rubber for artificial turf fields. The SBR rubber is considered risky.

According to Giovanni Lolli, undersecretary of Sports, “This is a serious problem. The commission has done diligent work: the next administration should reconvene the commission.”

Italian text:

Resi noti i risultati della commissione creata dall'ex ministro Storace

I tecnici del ministero della Salute rilanciano il rischio cancro

Erba sintetica, allarme confermato

"Quei campi vanno bonificati"

di CORRADO ZUNINO

ROMA - L'ultimo atto del ministero della Salute uscente certifica l'allarme: i campi in erba sintetica costruiti in Italia sono potenzialmente cancerogeni. La commissione istituita da Francesco Storace, poi costretto a lasciare la guida del ministero, ieri mattina ha discusso in maniera accesa un paio d'ore e poi ha deciso - all'unanimità - di lasciare un documento-avvertimento al prossimo ministro della Sanità.

In quel ponderoso lascito si dicono quattro cose decisamente serie. Nell'intaso di gomma che sostiene il manto d'erba artificiale, primo, ci sono quantità pericolose, in alcuni casi picchi elevati e comunque sempre oltre la soglia stabilita per legge, di Ipa (idrocarburi policiclici aromatici dannosi per reni, fegato e polmoni), toluene (composto volatile altamente tossico) e metalli pesanti. Quindi, seconda informazione, si stanno chiudendo gli studi su come questi elementi possano essere inalati dai calciatori in attività sui campi e le prime indicazioni dei ricercatori dell'Istituto superiore di Sanità preoccupano: le polveri che si sollevano giocando a pallone sono rischiose.

Terzo, sulle basi di queste scoperte scientifiche si deve realizzare una legge sui campi in erba artificiale, oggi inesistente. Infine, medici, avvocati del ministero dell'Ambiente e colonnelli dei Nas - tutti componenti della commissione - consigliano al prossimo ministro di emettere un'ordinanza per la bonifica dei campi pericolosi.

Il professor Roberto Verna, ordinario di Patologia clinica della Sapienza di Roma, presidente della commissione, dice: "Ipa e toluene sono pericolose per la salute, questo è acclarato. I Nas hanno prelevato campioni di gomma in tredici campi: tutte le aziende e tutti i tipi di intasi hanno mostrato problemi. Non vogliamo seminare paure, ma è necessario trovare un modo per bonificare i terreni di gioco. Diciamo che tutti i campi italiani devono essere controllati, i 350 ufficiali e le decine di abusivi. Il metodo di controllo dovrà essere unico".

Per definire i campi pericolosi il gruppo di lavoro si è ispirato alla normativa sul verde pubblico e alle tabelle dei parchi. Questo documento sarà inviato alla Fifa, l'organizzazione mondiale del calcio, e all'Unione europea, che già ha vietato la produzione di gomme con idrocarburi aromatici a partire dal 2007. "È il primo lavoro realizzato in Europa da una commissione indipendente. Le gomme, oggi, devono essere trattate come si fa con le mucche: dobbiamo sapere dove si raccoglie la materia prima, come si lavora, come arriva il prodotto finito. Ci vuole un'etichetta del prodotto".

Il presidente della Lega nazionale dilettanti, Carlo Tavecchio, gestore discusso del grande affare campi artificiali, ha già parlato di rottamazione. "Dovremo aprire almeno duecento terreni e aspirare le sostanze nocive. Ripartiremo i costi tra Federcalcio, produttori dei campi e gestori". L'impresa è titanica: ogni campo a undici ha 130 tonnellate di intaso e costa tra i 300 e i 650 mila euro. Le aziende medio-piccole sono in grave difficoltà: "Abbiamo fatto forti investimenti quando i regolamenti erano provvisori e oggi i comuni interrompono i pagamenti e le banche ci chiedono di restituire i prestiti concessi".

Intorno alla scoperta della tossicità dei campi è in corso, infatti, una dura battaglia industriale: produttori di gomma vergine contro riciclatori, grandi contro piccoli. In queste ore si sono fatti avanti, per esempio, i gestori del prato dell'Olimpico "realizzato con un prodotto misto di erbe naturali e artificiali che non ha bisogno di sottofondo" e alcune aziende che hanno messo a brevetto campi con fondi in sughero.

La commissione del ministero della Salute ha scoperto, ancora, che una buon parte dei "parchi gioco" del territorio - le aree con scivoli e giostre presenti nelle piazze italiane - poggia su tappetini in gomma prodotti dalle stesse aziende che forniscono i campi in erba artificiale e realizzati con le stesse gomme riciclate: l'Sbr considerato a rischio. Giovanni Lolli, candidato sottosegretario allo Sport, dice: "Il problema è serio, questa commissione ha lavorato con serietà, il prossimo governo dovrà reinsediarla".

(3 maggio 2006) |

Editor's Note: No sooner than you had bought the claim of turf sellers that old and out artificial turf carpet can be disposed off as fuel, here comes this item. This item covers a court-mandated change in a deacde-old EPA policy that allowed old tires to be burned as "alternative fuel." The rise of in-filled synthetic turf field industry came about a the same time as that policy, which made little of environmental and health hazard of used tires. As long as used tires were being "recycled" out of municipal disposal centers due to their hazardous nature and volume, EPA cared not!

Recyclers Used to Burning Rubber Are Now Idling, by Cindy Skrzycki, Washingtonpost.com, September 18, 2007

http://www.washingtonpost.com/wp-dyn/content/article/2007/09/17/AR2007091701879.html

A new industry that recycles old tires into fuel, saving companies millions of dollars and reducing a billion-tire national stockpile, is in limbo after a U.S. appeals court tossed out some federal clean-air rules.

In the past decade, owners of industrial boilers considered themselves do-gooders because they had the Environmental Protection Agency's blessing to burn alternative fuels, including old tires. Yet environmental groups said the practice dodged clean-air requirements by classifying incinerators as boilers, which have less stringent emission rules.

On June 8, a panel of the U.S. Court of Appeals for the District of Columbia agreed, heading off a new EPA rule that was to go into effect last week and forcing the agency to come up with a new definition of "solid waste."

"Tires will become a pariah if they are classified as a solid waste," said Michael Blumenthal, senior technical director for the Rubber Manufacturers Association in the District, which represents major tire manufacturers. He said the impact of the ruling would be "monumental."

Michael Sorcher, president of M.A. Associates, a marketer of tire-derived fuel based in Overland Park, Kan., said the new industry has been thriving. It saves more than $100 million a year for such customers as International Paper of Memphis, and Holcim of Jona, Switzerland, the world's second-largest cement maker, he said.

"This regulatory change doesn't just affect end users but the whole industry structure," Sorcher said, referring to makers of crumb rubber and other forms of recycled tire rubber. "It would be devastating for the industry in general."

The court said facilities burning tires, wood, bark and other industrial wastes had been improperly classified by the EPA. The agency allowed facilities that "recovered energy" to be designated as boilers instead of following language in the Clean Air Act designating units that burn any solid waste as incinerators.

"Had Congress intended to exempt all units that combust waste for the purpose of recovering thermal energy, it could likewise have expressly provided for their exemption in the statute," the ruling said.

Robert Wayland, leader of the EPA's Energy Strategies Group in the Office of Air Quality Planning and Standards, said the agency wanted to encourage the use of alternative energy sources, including tire-derived fuel. "We thought we had the purview to include these," Wayland said.

Cement kilns are the biggest users of tire-derived fuel, burning as many as 60 million tires a year, said Michel Benoit, executive director for the Cement Kiln Recycling Coalition in the District.

The last thing his members want, Benoit said, "is another rule and charting into some unknown territory" that would make replacing coal with tires uneconomical.

"Nobody has been ruled in or out at this point," said the EPA's Wayland, adding it will take at least two years to propose and complete a new rule that defines fuel and waste.

Jockeying over the new proposal has already begun. The Rubber Manufacturers Association told the EPA on June 25 that it should modify any new rules to exempt tires from its definition of solid waste.

The growth of markets for tire-derived fuel was nurtured by the EPA in the past 20 years to solve another environmental problem -- the billion-tire stockpile was a fire and disease risk.

Environmentalists were unsympathetic to the plight of tire recyclers and their customers.

"If they burn tires, they have to meet emission standards," said James Pew, staff attorney with Earthjustice, a District environmental law firm that argued the case with the Natural Resources Defense Council, a nonprofit group. "It's not our goal to crack down on them, just to get a better environmental result."

The biggest users of tire-derived fuel said they will have to calculate the energy savings against the higher costs of being reclassified as an incinerator.

"If it's 10 percent of the fuel they use and it's millions of dollars for more controls, mills will say it's just easier to switch fuels," said Timothy Hunt, senior director for air-quality programs at the District-based American Forest and Paper Association, which represents pulp, paper and wood mills that use biomass and tires as fuel. "Every paper mill will face that decision."

He said that though states may step in with interim controls, facilities don't have a rule to comply with until the EPA comes up with a new standard.

Whatever the outcome, at least one company thinks the decision will encourage a different form of recycling tires: freezing and then pulverizing them into powder that can be use in paint, tile, decking, automotive parts -- and new tires.

Lehigh Technologies, a private company in Naples, Fla., uses about 7 million tires annually. One official there says the growth potential for its process is immense and doesn't have environmental consequences.

"We're interested in converting the rubber into more beneficial uses," said Patrick George, Lehigh's chief financial officer. "We're just trying to figure out how this affects our business."

Cindy Skrzycki is a regulatory columnist for Bloomberg News. She can be reached atcskrzycki@bloomberg.net.

|

Divers removing failed tire reef project

By Brian Sokoloff., Associated Press Writer (Fri Jun 8, 9:15 AM ET)

Fort Lauderdale, Florida -- It took only days to create what was touted as the world's largest artificial reef in 1972, when a well-intentioned group dumped hundreds of thousands of old tires into the ocean. Now divers expect to spend years hauling them to the surface. The tires turned out to be a reef killer, turning a swath of ocean floor the size of 31 football fields into a dead zone. Military crews began retrieving the tires this week from about 70 feet underwater, where they had broken loose from bundles and wedged along a natural reef. As of Thursday, they had pulled up about 1,600 of the estimated 700,000 tires that must be hauled to the surface. The tires are "a constantly killing coral-destruction machine," said William Nuckols, who is coordinating the cleanup. "They had to come up." The dumping of nearly 2 million tires began in 1972 with much fanfare by a group called Broward Artificial Reef Inc., which had the approval of the Army Corps of Engineers, support from Goodyear and help from hordes of volunteer boaters.

Read the rest of the story on Yahoo News at http://news.yahoo.com/s/ap/20070608/ap_on_re_us/tire_reef_blunder

|

Editorial Note: On Toxcity of Rubber Crumb

The rubber crumb is toxic. There is little doubt about it. What toxicological studies on rubber crumb measure is the health hazard of rubber crumb to humans and other living things.

Toxicity of rubber crumb already has been shown in aquatic life. This conclusion was reached in 2003 Canadian study titled “Toxicological Evaluation for the Hazard Assessment of Tire Crumb for Use in Public Playgrounds,” by Detlef A. Birkholz, Kathy L. Belton and Tee L. Guidotti, and published in the Journal of Air & Waste Management Association, vol. 53: 903-907 (July 2003).

The sellers of artificial turf often cite this study as proof that rubber crumb does not pose a health hazard to humans. Tthe researchers Birkholz, Belton and Guidotti designed a hazard assessment study to evaluate the potential human health and environmental concerns associated with the use of tire crumb in playgrounds. The human health concerns were addressed using conventional hazard analyses, mutagenicity assays, and aquatic toxicity tests of extracted tire crumb. They concluded that the hazard to children appeared to be minimal. However, toxicity to all aquatic organisms (bacteria, invertebrates, fish, and green algae) was observed; but the toxicity disappeared with aging of the tire crumb for three months in place in the playground. The study concluded, "the use of tire crumb in playgrounds results in minimal hazard to children and the receiving environment." For the abstract of the study go to http://secure.awma.org/journal/ShowAbstract.asp?Year=2003&PaperID=1089. For the full version of the study in PDF click here.

The assurance of "minimal hazard" to humans does not mean absence of toxicity. As to humans and other air and land animals, the question of harm depends on the form, amount, concentration, and duration of exposure to the harmful substances in rubber crumb and its leachate.

There was a time when DDT, asbestos, Agent Orange, smoking cigarette, second-hand smoke and transfats were all accepted and acceptable. In the City of Newton, Massachusetts, the public schools are latex-free environment.Yet, it is perfectly okay that Newton children and youth should wallow in polypropylene and plastic fibers and rubber crumb of an artificial turf field or tire crumb dust from rubberized playgrounds!

One of the glaring omissions from toxicological studies of rubber crumb is reference to the adhesion of rubber crumb and synthetic fibers to the herbicide, fungicide, algaecide, and pesticides that are used in the maintenance of artificial turf fields. One should be concerned about the health hazards of rubber crumb also as a delivery mechanism for the residue of the toxins that are used to treat the fields.

|

|

| Loose and plenty |

|

A typical multipurpose “new-generation” synthetic field contains a mix of some 10 tons of rubber crumb (granule infill) and 3 tons of sand.. The rubber crumb-and-sand mix is applied to the surface of the field and it is in the form of loose granule not larger than a small mouse dropping. The crumb and sand move about – laterally and vertically. Upon impact from a dropping body, slid or kick, the crumb and sand fly off in a puff-like dust. In most synthetic turf fields, the rubber crumb that has moved or washed off the field can be scooped up by the handful. The periodic treatment of the infill is therefore a crucial part of a well-maintained synthetic turf field.

The thumbnails below depict the cross-sectional layout of a variety of rubber infill artificial turf fields. The fourth from left, shows the emerging modular natural grass format, whereby the natural grass field is rendered reparable by the help of previously grown and inventoried squares of natural grass.

|

|

| A toxic cocktail |

|

Typically, a rubber infill artificial turf consists of rubber crumb from recycled tires. There are other forms of rubber or combination of rubber and other substances but they are expensive enough to make the cost of an artificial turf field much prohibitively higher than natural grass fields. About 250 million scrap tires are generated in the US every year. The disposal of used tires in landfills or by incinerators has been a problem for a long time. Some 80 percent are ground up and recycled – 30 percent mixed with asphalt for highways; 30 percent mixed with plastics for molded products; and 15 percent used for athletic surfaces, including artificial turf. An average synthetic turf football or soccer fields uses 45,000 recycled tires that might otherwise take up space in the landfill. Ironically, the very article that is not readily disposable is being re-introduced into our environment in the form of granulated rubber crumb on our playing fields.

|

“Tyre Dust,” by Pat Thomas. Ecologist. November 1, 2005

Most of us could list at least half a dozen reasons why cars are bad for our health and bad for the environment. Cars are inefficient forms of transportation, they consume our rapidly declining stocks of fossil fuels, they are difficult to dismantle and recycle and they generate major pollutants such as hydrocarbons, nitrogen oxides, and carbon monoxide. What might not be on that list, however, are tyres. Even if you are a car owner it is unlikely that you think about tyres at all until they need air, go flat or require replacing.

Tyres are so fundamental to the function of every vehicle in the world – from the smallest Smart car to the biggest lorry and fastest jet – that it would never occur to many of us to ask what goes into them, or more importantly what comes out of them when the rubber meets the road. Yet pollution from tyre dust is linked to an expanding range of health problems including allergies, asthma and even heart disease.

Where does the tread go?

What goes into a tyre must also eventually come out. When a rubber tyre, bearing the weight of a vehicle, rolls across an asphalt or cement surface, tiny fragments of rubber, known variously as tyre dust or particulate matter, break off. Some become airborne and some are deposited at the side of the road, ready to be swept up by passing vehicles. Particulate matter is a very insidious form of air pollution and tyres contribute significantly to this form of pollution.

In the 1970s and early 1980s, when scientists working for the tyre industry TYRE DUST WHERE THE RUBBER MEETS THE ROAD Think vehicle pollution and you think of the internal combustion engine. What comes out of the exhaust pipe is undoubtedly bad, but the stuff that comes off he tyres may be even worse for your health. PAT THOMAS REPORTS and the Environmental Protection Agency (EPA) studied this phenomenon, it was concluded that tyre dust fragments were too large to enter the human lung and so presented no threat to human health.

Today we know differently. Several studies published in the last decade have demonstrated that about 60 per cent of these fragments are so small that they can enter the very deepest parts of the human lung. The particles of greatest concern are those that measure 10 microns or less in diameter (a human hair, by comparison, is about 70 microns thick and the dust motes that can be seen spiralling through the air when the sun shines through the window measure around 10 microns).

A Dirty Mixture

The microscopic dust that comes off tyres contains a unique mixture of substances that have a more powerful effect on the body than naturally occurring dust. To form the rubber into hard-wearing vehicle tyres, an extensive range of chemicals including xylene, benzene, petroleum naphtha, chlorinated solvents (for example 1,1,1- trichloroethane), polycyclic aromatic hydrocarbons, anthracene, phenanthrene, benzo[a]pyrene, phenols, amines, oil, acids and alkalis (eg sodium hydroxide), polychlorinated biphenyls, halogenated cyanoalkanes, processing aids, and plasticisers. Tyre processing also involves several heavy metals including zinc, cadmium, lead, chromium and copper.

By way of illustration, in one experiment published in 1998 in Environmental Health Perspectives, researchers from the University of Texas’ Houston Health Science Center exposed immune cells called macrophages to ash collected from the Mount St Helen’s eruption and to airborne dust from St Louis and Washington, DC. The volcanic dust had no effect on the cells but the urban dust caused the macrophages, which normally keep immune reactions under control, to die. The likely result of this damage is an overly aggressive immune response, with the potential to cause inflammatory damage to the lungs.

It is hardly surprising, then, to find numerous studies linking the rise in asthma and other allergies over the last 25 years to particulate matter in the air. In the past this problem was blamed on exhaust pipe emissions, particularly diesel exhaust. But now researchers believe that the microscopic dust generated by tyres is equally, if not more, influential. In areas of high traffic it can cause asthmatic attacks and pose a serious threat to elderly patients whose lungs are already weakened by age and illness. Babies and young children are also at increased risk; per pound of body weight, they inhale more particulates than adults. Studies continuously show that asthma rates are higher in those living close to busy, congested roads. In one 1994 study published in the Archives of Environmental Health, children admitted to one Birmingham hospital for severe respiratory problems were much more likely to be living near busy roads than healthy children or those admitted to hospital for other reasons.

Allergies on the rise

n addition to generalised allergic responses, tyre dust also produces some very specific allergic responses. Tyres are made from a combination of natural latex, derived from rubber trees, and synthetic rubber derived from petroleum. At least 70-75 per cent of all natural rubber produced today is used to make tyres – the rest goes to making latex gloves and condoms, as well as paint and adhesives.

Latex allergy was first noticed in the late 1970s. As the fear of AIDS became a major medical concern, more and more medical workers started wearing latex gloves and this increased exposure to latex meant that allergies became much more common. Today, because of their continuous exposure to latex gloves, tubing and other rubber coated medical and surgical paraphernalia, up to 10 per cent of all health care workers show signs of an allergic reaction to latex. But studies of individuals living near busy roads has shown that the latex portion of tyre dust can also cause allergic reactions ranging in severity from rhinitis (runny nose) and conjunctivitis (tearful eyes), to hives (urticaria), bronchial asthma, and occasionally even a life threatening condition called anaphylactic shock.

Equally alarming is the way that latex allergy can produce cross-reactions to a wide variety of fruits, vegetables and legumes. This phenomenon, referred to as latex-fruit syndrome, means that some people who become sensitised to latex will also experience allergic reactions to foods such as banana, kiwi, chestnuts, avocados, peaches, tomatoes, potatoes, peppers and peanuts. Latex-allergic people also occasionally have cross-reactions to some kinds of pollen and herbal remedies. No studies have ever been done that conclusively link tyre dust to latex-fruit syndrome, though it is tempting to speculate that individuals living near busy roads might make a silent, albeit significant, contribution to the increasing prevalence of food allergies in the developed world.

Deadly Dust

The unique combination of known carcinogens, neurotoxins, heavy metals and other poisons in tyre dust can also be linked to more serious diseases. In a 1994 report on the adverse effects of particulate air pollution, published in the Annual Reviews of Public Health, researchers found that for every cubic metre of air, an increase of 20 micrograms (mcg) of particulate matter meant a one per cent increase in deaths from all causes. In this study deaths from respiratory failure, but also heart failure, were much more common as particulate levels increased. This estimate is echoed in the conclusions of a recent report by the non-profit Health Effects Institute in Cambridge, Massachusetts, which found that death rates in the 90 largest US cities rise by 0.5 per cent with only a tiny increase – 10 mcg per cubic metre of air – in particles less than 10 micrometres in diameter. However, these findings may underestimate the real risk.

This month a large, long-term study of residents in the Los Angeles, published in the journal Epidemiolog, found that for each increase of 10 micrograms per cubic metre of fine particles in the neighbourhood’s air, the risk of death from any cause rose by 11 to 17 per cent. The risk of death from diabetes rose more than two-fold and the risk of death from heart disease rose by an astounding 25 to 39 per cent. Similar findings were published in 2003 in Circulation: Journal of the American Heart Association, where researchers looking at 16 years of data on more than a million people concluded that long-term exposure to air pollution posed a greater risk of death from heart disease than it did for death from respiratory ailments.

New research continues to emerge on the mechanics of the microscopic dust-heart failure connection. A healthy heart is able to vary its beats per minute widely, depending on the demands being placed on the body. But when researchers at Harvard Medical School took electrocardiogram (ECG) and blood-pressure readings from 21 Boston residents aged over 50, heart rate variability decreased dramatically when the patients were exposed to air with high levels of very fine particulate matter. Decreased heart rate variability is a known risk factor for sudden heart failure.

Why particulate pollution should have such an effect on the heart rate is still a mystery. One possibility is that when you inhale these very small particles deep into your lungs, some of them make their way into the bloodstream, where they find easy access to organs such as the heart. Once they become lodged in cardiac muscle, these particles may also initiate an inflammatory response that reduces blood flow and speeds the progression of atherosclerosis. Humans aren’t the only ones affected. While studies into the effects of particulate on animals in their natural habitats are thin on the ground, laboratory studies show that inhaled dust can damage both the hearts and lungs of dogs, mice and other animals. In one investigation, dogs exposed to levels of particulates no higher than those found in many US cities experienced significant changes in their heart rhythms.

Spare Tyres

Tyre dust is a significant source of pollution. But what happens at the end of a tyre’s lifecycle produces an altogether different kind of pollution. Piles of waste tyres are rapidly accumulating around the world. As of 2003, about 290 million tyres were discarded in the US every year (roughly one per person). In the UK around 40 million spare tyres accumulate each year. Since 2003 it has been illegal to dump whole tyres in landfills in the UK and by next year it will be illegal to dump chipped tyres into landfills as well.

The disposal of tyre waste is now a major problem throughout the world and one to which there are no apparent solutions. Tyres are designed not to fall apart and this means that they are difficult to dispose of. Although they can remain substantially intact for years beyond their useful life, the number of dangerous chemicals in tyres mean that they can’t be safely burnt. Nevertheless, cement makers and paper mills are happy to use waste tyres as fuel – a disastrous enterprise that produces even higher levels of particulate pollution. Buried in the ground, their constituent chemicals leech out on the ground and water table. Used to make artificial reefs, they can provide homes for certain types of marine life, but are toxic to many fish.

At the moment the best use of old tyres is to extend their life by retreading them. This process involves grinding down the surface, or casing, of the worn tyre until it is smooth and gluing a new veneer of tread onto it. While retreading a tyre uses far fewer resources than buying a new tyre, it is not entirely environmentally friendly since it still involves the use of non-renewable resources to make the new tread, and strong adhesives and other toxic chemicals to attach it to the old casing (and, of course it makes no impact whatsoever on the problem of tyre dust).

A quality car tyre can be retreaded about three times, and tyres for larger vehicles can be retreaded as many as 12 times. Unfortunately, according to the Used Tyre Working Group, a joint industry and government initiative sponsored by the main tyre industry associations, just 18 per cent of Britain’s tyres are retreaded. Around 48,500 tons are converted into crumb rubber – used in carpet underlay and to make springy surfaces for running tracks and children’s playgrounds. However, this makes little dent in the 435,000 tons of waste tyres produced by the UK each year.

Environmental Impacts

At every stage of a tyre’s life cycle, from the sourcing of raw materials to the mountains of waste tyres that blot the landscape, tyres are bad news for the environment. Tyre manufacture relies on fast disappearing natural resources, such as rubber trees, as well as non-renewable resources such as petroleum and mined minerals. It also generates significant levels of localised pollution. Nevertheless, it is during and at the end of their life that tyres generate the greatest amount of harmful pollutants.

Material/Source Natural rubber

Predominantly obtained from the sap of the Hevea brasiliensi tree.

Application

Currently makes up about 30 to 40 per cent of the total rubber used.

Potential impacts

Loss of habitat in tropical forests.

Use of pesticides and hormone- based growth promoters (used to increase sap production).

Transportation to markets.

Pollution from rubber processing plants.

Material/Source Synthetic rubber

All synthetic rubbers are made from petrochemicals.

Application

Accounts for approximately 60 to 70 per cent of the total rubber used

Potential impacts

Resource depletion of petroleum.

Energy consumption, emissions and waste during manufacture.

Material/Source Steel cord and beading including the coating materials and activators, copper/tin/zinc/chromium.

The steel is premium grade and is only manufactured in a limited number of plants around the world due to the high quality requirements.

Application

Provides rigidity and strength to the tyres. In a car tyre, steel cord makes up about 15 per cent by weight.

Potential impacts

Energy use and toxic emissions during processing and transportation.

Difficult to recycle.

Leaching of metals during disposal.

Material/Source Other reinforcing fabrics

Predominantly sourced from petrochemicals.

Application

For structural strength and rigidity. Makes up about five per cent of a radial tyre (one reinforced with steel).

Potential impacts

Toxic emissions/energy use during processing and transportation.

Material/Source Carbon black

Generally sourced from petroleum stock.

Application

Imparts durability and wear and resistance to degradation. Makes up about 28 per ent of a passenger tyre, although

the amount is higher in the rubber that makes up the wearing surfaces.

Potential impacts

Toxic emissions/energy use during processing and transportation.

Material/Source Zinc oxide

Mined/refined material.

Application

Adds resistance to UV degradation, controls the vulcanisation process and enhances blending. Zinc oxide makes up

about 1.2 per cent of a passenger tyre.

Potential impacts

Toxic emissions/energy use during processing, manufacture and disposal.

Leeches into the soil and water from waste tyres.

Material/Source Sulphur (including compounds)

Used to vulcanise the rubber.Mining erodes the soil.

Application

Makes up about one per cent of a passenger tyre.

Potential impacts

Toxic emissions/energy use during production/procession.

Toxic emissions released when tyres are burned for fuel or disposal.

Material/Source Other additives and solvents

Age resistors, processing aids, accelerators, vulcanising agents, softeners and fillers are used in the various rubber compounds to modify handling manufacturing and end product properties.

Application

Additives make up about eight per cent of a passenger tyre.

Potential impacts

Various impacts associated with manufacture and transportation including energy use, non-renewable resources and

toxic emissions.

Impacts associated with use and disposal of the solvents.

Emissions from tyres in use, during recycling and in final disposal.

Frustration

The impact of particulate matter – from tyres and other sources – on human health is undeniable. It is particularly frustrating, then, that there appears to be no immediate answer to, or recognition of the problem of tyre dust.

In June of this year a report, Particulate Matter in the United Kingdom, produced by the Air Quality Expert Group, the body that advises government on matters of air quality, concluded that although particulate matter levels have been decreasing over the past few decades, background levels are still very high and more work needs to be done to ensure that national targets for reducing particulate matter are met.

The report also notes that relatively little data exists to quantify the emission rates, size, distribution and composition of particulates from tyre wear. It also reveals that figures for emissions from non-exhaust sources like tyres are not even taken into account in the Atmospheric Emissions Inventory of the UK’s largest city, London. Even without this vital London data, the group estimates that tyre and brake wear emissions accounted for more than 23 per cent of the total road transport emissions.

When government think tanks think about tyres, they focus on the environmental menace of waste tyres (see box on page 15). This is undoubtedly important, but clearly its scope is woefully inadequate. We’ve got to put the bigger picture of tyre lifecycles onto the agenda before we can even begin to reduce their impact on health and environment.

Pat Thomas is the Ecologist’s Health Editor.

Source: http://www.theecologist.org/archive_detail.asp?content_id=543

|

According to Melos GmbH, Melle, Germany (www.melos-gmbh.com), there are essentially four varieties of granule infill materials:

The SBR infill material is the most cost-effective infill granules. The material has a high rubber content that gives it high elasticity. The carbon black gives it resistance to UV and the weather. Since this product is manufactured from recycled materials (principally old car tires) some variation in quality cannot entirely be ruled out. Depending on the length of time the original material was used, it may become brittle after a relatively short time. Because the material was originally manufactured for a different purpose this granule’s polycyclic aromatic hydrocarbons (PAH) and zinc contents are extremely variable and may be quite high. It is not possible to flameproof this material.

The PUR-coated SBR granules combines the elasticity of SBR materials with a free choice of colors. In price, this material lies between SBR and EPDM infill granules, which makes PUR-coated SBR the logical alternative where colored (green or brown) granules are to be used and where the material’s environmental toxicity is of secondary importance. It is not possible to flameproof this material.

The EPDM infill granule has been around since the time rubberized artificial turf was first introduced. It is produced especially for playing fields and so the material can be tailored to individual requirements, so it is possible to supply flame-retardant and foamed granules in any desired color. EPDM infill granules are naturally non-fading and weatherproof. The use of suitable pigments prolongs colors, and choosing appropriate cross-linking chemicals produces a material with “excellent” eco-toxical properties and PAH values under 1 mg/kg.

The thermoplastic elastomers (TPEs) are the very latest development in the field of infill granules. It can be made to specified elasticity and flame-retardant. This infill material has low wear and high elasticity, and its thermoplastic properties enable it to be recycled.

|

|

| Heavy metal -- not music |

|

Heavy metals and other substances. Recycled rubber infill contains substances like aluminum, cadmium, chromium, copper, iron, magnesium, manganese, molybdenum, selenium, sulfur and zinc, in addition to lead that may have been absorbed into the rubber while in use as tire. Many of these are toxic.

Environmental metals are amongst the most wide spread and deadly pollutants known to man. Heavy metals like copper, zinc, lead, cadmium, mercury and alike could increase the production of free radicals a million fold. The free radicals are considered to be a root cause of such chronic diseases as rheumatism to arthritis, diabetes, MS, Alzheimer's, Parkinson's, and cancer.

According to Dr. Linda Chalker-Scott, a horticulturist with Washington State University [see her article below], “It is abundantly clear that rubber should not be used as a landscape amendment. There is no question that toxic substances leach from rubber as it degrades, contaminating the soil, landscape plants and associated aquatic systems.”

The rubber crumb and other rubberized products used in the synthetic turf installation contribute to the heat island effect. The rubber-and-sand infill add to the maintenance cost of a field. The principal objections to the use of rubber crumb is environmental degradation and health risks to humans and animals.

The following articles evaluate the toxicity and other issues related to the use of rubber crumb in synthetic turf playing fields. The risks are alarming.

|

Hazardous Chemicals in Synthetic Turf

by William Crain and Junfeng Zhang

Summer 2006

A new generation of synthetic turf is becoming popular in the U.S. Brands such as FieldTurf are springier than the old AstroTurf and feel more like real grass. They also promise low maintenance costs. New York City is so attracted to the new synthetic turf that it is installing it in 79 parks, often substituting it for natural soil and grass. [1].

However, the new artificial grass raises health concerns. In particular, the base of FieldTurf and similar brands includes recycled rubber pellets that could contain harmful chemicals. What's more, we have observed that on many New York City fields, the rubber pellets are also present on the surface. When one of us (William Crain) was picking up some pellets by hand, a boy told him that after playing in the park, he finds the pellets in his shoes at home at night. Because the rubber pellets are much more accessible to children and athletes than we had supposed, we decided to analyze a sample for two possible sets of toxicants -- polycyclic aromatic hydrocarbons (PAHs) and toxic metals.

We collected our first sample from a new FieldTurf surface in Manhattan's Riverside Park in May, 2006. [Note: This is an error. The brand of artificial turf sampled in Riverside Park was A-Turf, not FieldTurf.] To gain information on the reliability of our results, we gathered a second sample in June, 2006 from a different part of the park.

The PAHs were extracted in a Soxhlet apparatus with organic solvents. The metals were extracted by means of nitric acid with the aid of a high-efficiency microwave oven (Marsx Microwave). Both methods were used to estimate the maximum amounts of the chemicals contained in the bulk material (rubber pellets). The analyses were conducted at the Environmental and Occupational Health Sciences Institute of Rutgers University.

The PAH results for our first sample are listed as Sample 1 in Table 1, below. As the table shows, six PAHs were above the concentration levels that the New York State Department of Environmental Conservation (DEC) considers sufficiently hazardous to public health to require their removal from contaminated soil sites. [2]. It is highly likely that all six PAHs are carcinogenic to humans.

The PAH results for Sample 2 are also listed in the table. Although the concentration levels in Samples 1 and 2 varied somewhat, the results for Sample 2 replicated the finding that the concentration levels of the six PAHs are above the DEC's tolerable levels for soil.

Table 1. Concentrations of PAHs (ppm: parts per million)

Sample 1 Sample 2 DEC

A-Turf A-Turf Contaminated

Rubber Pellets.…. Rubber Pellets Soil Limits

Benzo(a)anthracene 1.23 1.26 1.0

Chrysene 1.32 7.55 1.0

Benzo(b)fluoranthene 3.39 2.19 1.0

Benzo(a)pyrene 8.58 3.56 1.0

Benzo(k)fluoranthene 7.29 1.78 0.8

Dibenzo(a,h)anthracene 3.52 1.55 0.33

The analyses also revealed levels of zinc in both samples that exceed the DEC's tolerable levels. Lead and arsenic also were present, and many scientists believe that these metals should not be introduced into the environment at all.

We want to emphasize that the findings are preliminary. PAHs in rubber might not act the same way as in soil, and we do not yet have information on the ease with which the PAHs in these rubber particles might be absorbed by children or adults -- by ingestion, inhalation, or absorption through the skin. However, the findings are worrisome. Until more is known, it wouldn't be prudent to install the synthetic turf in any more parks.

We have informed the New York City Parks Department of our findings, but as far as we know, the Parks Department has not altered its plans to continue the installation of artificial turf in numerous parks.

References:

[1] New Yorkers for Parks. A New Turf War: Synthetic Turf in New York City's Parks -- Special Report, Spring 2006. www.NY4P.org.

[2 ] 6 NYCRR Part 375, Environmental Remediation Program, Draft Revised June 14, 2006, Department of Environmental Conservation, Table 375-6.8 (a) and (b).

Source: The above study appeared in Rachel’s Democracy & Health News, No. 871: Hazards of Synthetic Turf, September 07, 2006. Rachel’s Environmental & Health News is a publication of Environmental Research Foundation, New Brunswick, New Jersey. The authors of the study: William Crain, Ph.D., is professor of psychology at The City College of New York and president of Citizens for a Green Riverside Park. Junfeng (Jim) Zhang, Ph.D. is professor and acting chair, Department of Environmental and Occupational Health, the School of Public Health, the University of Medicine and Dentistry of New Jersey and Rutgers University. On the web, this study is available at

http://www.rachel.org/bulletin/index.cfm?issue_ID=2568

|

Banned in Sweden! The government of Sweden has banned the use of recycled tires in artifical turf. This progressive measure is being matched by the manufacturers in Germany, where more and more of the rubber used in synthetic turf is virgin rubber. In the United States there are no regulations as yet to ban the use of recycled tires; however, there are strict regulations governing the disposal and/or incineration of tires.

The following pages reproduced here below contain the background and conclusions of the Chemicals Inspectorate of Sweden. [Click here for the full PDF version].

|

Synthetic turf from a chemical perspective: a status report. Swedish Chemicals Inspectorate (March 2006).

Background. Synthetic turf is used for football pitches around the world. This turf has many advantages, being hard-wearing and easier to maintain than natural grass. These pitches allow the football season to be extended, independently of the weather.

Synthetic turf often contains rubber granulate from waste tyres, which in turn contain several substances with hazardous properties. A discussion is currently being carried out in several European counties, including Norway, Italy and Germany, concerning the properties of synthetic turf and the possible risks of using it. Many municipalities in Sweden have requested information and advice, as have manufacturers, representatives from football, and the general public. The Swedish Chemicals Inspectorate (KemI) has consequently prepared this report in order to discuss the properties and use of synthetic turf from a chemical perspective.

This report provides a comprehensive survey and an assessment based on current knowledge. It is based to a large extent on results of investigations and assessments that have recently been carried out in Norway. Information has also been obtained from companies that deliver and install synthetic turf surfaces, the Swedish Football Association, sports administrations, environmental administrations, representatives from the recycling industry, and from the Swedish Standards Institute (SIS). KemI has also been in contact with the Swedish Work Environment Authority, the Swedish Environmental Protection Agency, and the Norwegian Pollution Control Authority (SFT).

Suppliers, representatives from football and authorities exchanged experiences concerning synthetic turf at a meeting held at KemI on 18 January 2005. The scope of the report is limited to synthetic turf that contains granulate from recycled tyres used for football pitches. Synthetic turf that contains other material, such as new rubber, thermoplastics and rubber-coated sand, have not been assessed. Other uses of recycled tyres, such as their use in playgrounds, for horse-riding surfaces and other sporting activities, have also not been assessed.

KemI hopes that it will be possible to use this report as a basis for product development in synthetic turf companies, and for facilitating local decisions and assessments when laying synthetic turf surfaces.

Summary. Synthetic turf is used for football pitches around the world. This turf has many advantages, being hard-wearing and easier to maintain than natural grass. These surfaces allow the football season to be extended, independently of the weather.

Synthetic turf often contains rubber granulate from waste tyres, which in turn contain several substances of very high concern. A discussion is currently being carried out in several European countries, including Norway, Italy and Germany, concerning the properties of synthetic turf and the possible risks of using it. Many municipalities in Sweden have requested information and advice, as have manufacturers, representatives from football, and the general public. The Swedish Chemicals Inspectorate (KemI) has consequently prepared this report in order to discuss the properties and use of synthetic turf from a chemical perspective.

The report briefly describes the health and environmental properties of certain substances, it summarises results from some relevant investigations into synthetic turf, and it describes the work for standardisation that is currently being carried out in Europe. Furthermore, Swedish environmental quality objectives and guidelines for the assessment of water quality and air quality are presented. KemI’s overall assessment is based on the material presented here.

Conclusions. Recycling Tyres. It is often a good strategy to recycle material from worn-out products for reasons of energy economy and the efficient use of resources. This recycling, however, may conflict with attempts to minimise the risk of using chemicals. It is important before the new use of the material is started to determine whether it will lead to people or the environment being exposed to hazardous chemicals. A recycling perspective and a consciousness of chemical aspects should be included at the production stage, in order to be able to manage recycled material to a greater degree and in a safe manner.

Tyres contain substances of very high concern. Tyres contain several substances that are substances of very high concern. These substances may persist in the environment, they may be bioaccumulative, carcinogenic, reprotoxic, or mutagenic. This is true of, for example, polycyclic aromatic hydrocarbons (PAHs), phthalates and certain metals. These substances should not be released into the environment and thus waste tyres should not be used for synthetic turf surfaces. The environmental objectives set down by the Swedish parliament state that substances of very high concern should be phased out from newly produced articles.

Work is currently under way to reduce the levels of hazardous substances in tyres. The levels of PAHs will be regulated within the EU with effect from 2010. This means that the levels of substances of very high concern in tyres will, in time, decrease. It will, however, take time before PAHs disappear completely from rubber, and tyres contain more substances than just PAHs that have hazardous properties. It is important for this reason that the future recycling processes take place in a controlled and safe manner in order to avoid the spread and distribution of substances of very high concern.

Synthetic turf contains substances of very high concern, but this does not necessarily mean that it is a direct risk for human health and the environment. The direct risk depends on the extent to which humans and the environment are exposed to the hazardous substances.

Environmental Risks and Health Risks. The use of tyres in synthetic turf surfaces means that both humans and the environment will be exposed to recycled tyres in an uncontrolled manner that may lead to risks. It can be expected thatthe hazardous substances in the tyres are more readily released and spread when the tyres have been shredded to give a granulate with small granules than is the case when the use involves larger pieces of tyre in other contexts.

There is a local environmental risk. Current knowledge allows the conclusion to be drawn that synthetic turf that contains rubber from recycled tyres may give rise to local environmental risks. Investigations have shown that zinc and phenols can leach from the rubber granulate, and these substances can affect aquatic and sedimentdwelling organisms, if they reach neighbouring water courses. The total amount of these substances that leaches from synthetic turf is small, however, and thus any effect on the environment that they have is expected to be local. Other sources may also contribute to increased levels of these substances in water courses.

The health risks for players are probably low. Measurement of indoor air and exposure calculations have shown that there is probably a small health risk associated with simply being on or playing on synthetic turf surfaces that use rubber from recycled tyres. The exposure levels and any allergic reactions, however, have been poorly studied. Exposure to these substances from other sources, such as car exhaust, must also be taken into consideration to achieve a total assessment of health risks.

KemI’s Recommendations. Do not select synthetic turf that contains substances of very high concern when

laying new surfaces. Material that contains substances of very high concern should not be used, as specified by the environmental objectives of the Swedish parliament. This means that granulate formed from recycled rubber should not be used when laying new surfaces of synthetic turf.

The Norwegian authorities have issued a similar recommendation. The Netherlands has also suggested that a similar requirement is included in the EU standard “Surfaces for sport areas – Synthetic turf surfaces primarily designed for outdoor use".

New solutions must be developed and requested –the responsibility of companies. It is important that the recycled rubber in synthetic turf is replaced by material that truly is better from the point of view of health and the environment. It is the responsibility of companies to ensure that the products that are delivered are safe for people and the environment. The contents of new materials should be known and they should preferably have been assessed from the point of view of a total lifecycle effect on the environment. This means that companies must have expert knowledge about their products. Swedish companies should place demands on their suppliers and they should provide the drive required to develop better alternatives.

The sports administrations in the municipalities and others who are involved when new surfaces are to be laid should request information about the contents of chemicals, and they should pose demands during the purchasing process and during installation such that substances of very high concern are not released into the environment.

|

Potential health and environmental effects linked to artificial turf systems - final report, by Norwegian Building Research Institute (September 2004). [Click here for the full report in PDF].

The Norwegian Building Research Institute (NBI) carried out a study of potential health and environmental effects linked to artificial turf systems on behalf of the Norwegian soccer federation. The study covered three types of rubber granulate made from recycled rubber, one EPDM rubber granulate and two artificial turf fibers, which are in use in the Nordic region. The rubber granulates and artificial turf fibers were analyzed with regard to the total content of arsenic, cadmium, copper, chromium, mercury, nickel, zinc, PCB, polycyclic aromatic hydrocarbons (PAH), phthalates and phenols. Leachate tests and degassing tests were also carried out.

The study found the following with respect to the artificial turf fibers. They contained copper, zinc, individual phthalates, 4-t-octylphenol and iso-nonyl-phenol. The concentration of zinc and copper complied with the Norwegian Pollution Control Authority's normative values for most sensitive land use for both fiber types. The leachate from the fibers contained zinc. The concentration was higher than the Norwegian Pollution Control Authority's limit for zinc in water with Environmental Quality Class V (very strongly polluted water), but lower than the permitted zinc concentration in Canadian drinking water. As the measured concentration of environmental toxins (with the exception of copper) in the artificial turf fibers was lower than in the rubber granulates, and the artificial turf fibers in any case constituted a much smaller proportion of the artificial turf system in terms of mass.

The study found the following with respect to the artificial turf fibers. The total analysis showed that the rubber granulates based on recycled rubber contain lead, cadmium, copper, mercury, zinc, polycyclic aromatic hydrocarbons, certain phthalates, 4-t-octylphenol and iso-nonylphenol. The total concentration of lead, cadmium, copper and mercury in the recycled rubber granulates was below the Norwegian Pollution Control Authority's normative values for most sensitive land use.

The total concentrations of zinc and PAH in the recycled rubber granulates exceeded the Norwegian Pollution Control Authority?s normative values for most sensitive land use. The concentrations of dibutylphthalate (DBP) and diisononylphthalate (DINP) exceeded the PNEC values for terrestrial life taken from the EU's program for risk assessment. The concentration of isononylphenol was above the limits specified for cultivated land in the Canadian Environmental Quality Guidelines.

The leachate from the recycled granulates contained, PAH, phthalates and phenols. The concentration of zinc indicated that the leachate water was placed in the Norwegian Pollution Control Authority's Environmental Quality Class V (very strongly polluted water), but is lower than the permissible zinc concentration in Canadian drinking water. The concentration of anthracene, fluoranthene, pyrene and nonylphenols exceeded the limits for freshwater specified in the Canadian Environmental Quality Guidelines. An expanded risk assessment with an analysis of possible spreading paths and changes in leaching properties over time was found to be necessary in order to determine the degree to which the concentrations of zinc, anthracene, fluoranthene, pyrene, phthalates and nonylphenols in the leachate are actually harmful to people and the environment.

The recycled rubber granulates gave off a significant number of alkylated benzenes in gaseous form. Trichloromethane and cis-1.2-dichlorethene were also found.

With the exceptions of chromium and zinc, EPDM rubber contained smaller quantities of hazardous substances than the recycled rubber types overall. It also gave off much smaller quantities of volatile organic compounds.

The report suggested that further investigations of artificial turf concentrate on the rubber crumb component of the field. It recommended that measurements be taken of air quality above artificial turf fields in order to determine whether air quality is satisfactory.

|

The Myth of Rubberized Landscapes

by Linda Chalker-Scott, Ph.D.

The Myth: “Recycled rubber mulch is an environmentally friendly, non-toxic choice for landscapes.” Discarded rubber tires are the bane of waste management; according to the EPA, we generate 290 million scrap tires annually. Scrap tire stockpiles can pose significant fire hazards, such as the 1983 Virginia tire fire that burned for 9 months. Obviously finding a market for these slow-to-decompose materials is desirable, and many innovative uses have been developed, including rubberized asphalt, playground surfaces, and landscape mulches. From an engineering standpoint, crumb rubber as a soil amendment has performed favorably in reducing compaction to specialty landscape surfaces such as sports fields and putting greens.

Rubber mulches are touted by manufacturers and distributors as permanent (“doesn’t decay away”) and aesthetically pleasing (“no odor” - “looks like shredded wood mulch” – “earth tones and designer colors” – “special fade resistant coating”) landscape materials. Furthermore, we are told that rubber mulch is “safe for flowers, plants and pets” (though it “doesn’t feed or house insects”) and “dramatically improves landscaping.” It seems to be an environmentally-friendly solution to a major waste disposal problem.

The Reality: Rubber mulches have not proved to be particularly good choices for either horticultural production or landscape uses. In comparison studies of several mulch types, rubber tire mulch was less effective in controlling weeds in herbaceous perennial plots than wood chips. Similarly, sawdust made a better mulch for Christmas tree production in terms of weed control, microbial biomass, and soil chemistry. Another comparative study found rubber to be less effective than straw or fiber mulch in establishing turfgrasses.

Not only do rubber mulches perform less effectively in the landscape, they possess an additional, unwanted characteristic. Compared to a dozen other mulch types, ground rubber is more likely to ignite and more difficult to extinguish. In areas where the possibility of natural or man-made fires is significant, rubber mulches should not be used.

The Myth: “Permanence” of rubber mulch.

The Reality: Far from being permanent, rubber is broken down by microbes like any other organic product. Many bacterial species have been isolated and identified that are capable of utilizing rubber as their sole energy source. Such bacteria have been found in a variety of environments, including the cavity water of discarded tires. Although some of the additives used in tire manufacture are toxic to rubber-degrading bacteria, there are white-rot and brown-rot fungal species that can detoxify these additives. While isolating these microbes has been beneficial in developing natural mechanisms to recycle rubber products, it also points out the fallacy of assuming that rubber mulch is “permanent.” Furthermore, it alerts us to the very real possibility that car tires leach toxic compounds into the landscape.

TheMyth: “Non-toxicity” of rubber mulch.

The Reality: Current research at Bucknell University indicates that rubber leachate from car tires can kill entire aquatic communities of algae, zooplankton, snails, and fish. At lower concentrations, the leachates cause reproductive problems and precancerous lesions. A similar study exploring the use of tires as artificial reef substrates also found rubber leachate to negatively affect the survival of various seaweeds and phytoplankton. Marine and other saline environments are less sensitive to tire leachates, however, and the greatest threat of contamination appears to be to freshwater habitats.

Part of the toxic nature of rubber leachate is due to its mineral content: aluminum, cadmium, chromium, copper, iron, magnesium, manganese, molybdenum, selenium, sulfur, and zinc have all been identified in laboratory and field leachates. If rubber products have been exposed to contaminants during their useful lifetime, such as lead or other heavy metals, they will adsorb these metals and release them as well. Of these minerals, rubber contains very high levels of zinc – as much as 2% of the tire mass.

A number of plant species, including landscape materials, have been shown to accumulate abnormally high levels of zinc sometimes to the point of death. One USDA researcher who has studied zinc and other metals in soils and plant materials for decades strongly believes that ground rubber should not be used “in any composting, or in any potting medium, or casually dispersed on agricultural or garden soils” because of zinc toxicity. Acidic soils and aquatic systems are particularly sensitive, since heavy metals and other positively charged elements are less tightly bound to the soil and more available to plant and animal uptake.

Rubber leachates are complex solutions. They include not only the minerals and organic building blocks of rubber, but also various plasticizers and accelerators used during the vulcanizing process. In high enough concentrations, some of these rubber leachates are known to be harmful to human health; effects of exposure range from skin and eye irritation to major organ damage and even death. Long term exposure can lead to neurological damage, carcinogenesis, and mutagenesis.

Some of these materials break down quickly, while others are known to bioaccumulate. One of the more common rubber leachates is 2-mercaptobenzothiazole, a common accelerator for rubber vulcanization. In addition to its known human health concerns, it is highly persistent in the environment and very toxic to aquatic organisms: its environmental persistence may cause long-term damage to aquatic environments constantly exposed to rubber leachates.

Another family of organic leachates under scrutiny are the polyaromatic hydrocarbons (PAHs). These compounds, used as rubber softeners and fillers, have been repeatedly demonstrated to be toxic to aquatic life. PAHs are released continually into solution, and after two years in a laboratory test leachates were shown to be even more toxic than at the study’s inception.

It is abundantly clear from the scientific literature that rubber should not be used as a landscape amendment or mulch. There is no question that toxic substances leach from rubber as it degrades, contaminating the soil, landscape plants, and associated aquatic systems. While recycling waste tires is an important issue to address, it is not a solution to simply move the problem to our landscapes and surface waters.

The Bottom Line

- Rubber mulch is not as effective as other organic mulch choices in controlling weeds.

- Rubber mulch is highly flammable and difficult to extinguish once it is burning.

- Rubber mulch is not permanent; like other organic substances, it decomposes.

- Rubber mulch is not non-toxic; it contains a number of metal and organic contaminants

with known environmental and/or human health effects.

Source: the author is an Extension Horticulturist and Associate Professor at the Puyallup Research and Extension Center at Washington State University. On the web, the study is available at http://www.puyallup.wsu.edu/~Linda%20Chalker-Scott/Horticultural%20Myths_files/Myths/Rubber%20mulch.pdf. In an e-mail to Dr. Chalker-Scott, the Managing Editor of this site asked if the same conclusion about rubber mulch could extend to the use of rubber crumb in synthetic turf fields. Dr. Chalker-Scott responded in the affirmative, as the base product (recycled tires) for rubber crumb in synthetic turf is the same as in rubber mulch.

|

Environmental impact of highway construction and repair materials on surface and ground waters. Case study: crumb rubber asphalt concrete.

by M.F. Azizian, P.O. Nelson, P. Thayumanavan and K.J. Williamson